By Steve Jones, Senior Director, Industry Insights Research, Dodge Construction Network

In recent years, artificial intelligence has evolved from a concept in science fiction to an increasingly transformative tool across numerous sectors of the global economy. Popular media often portrays AI as a fearsome force that will replace human labor, thinking and judgment. However, a more nuanced and beneficial perspective is emerging: AI as augmented intelligence, enhancing human capabilities rather than replacing them. It points to a collaborative future where machines and humans work in harmony to achieve more than either could alone.

DEFINING AUGMENTED INTELLIGENCE

Unlike AI, which aims to replicate or surpass human intelligence, augmented intelligence is designed to support human decision-making and improve productivity. It can process and

analyze vast amounts of data swiftly and accurately, providing insights and recommendations that humans can then adapt to the situation at hand according to their experience and judgment. Put simply, augmented intelligence helps people make more informed decisions. It does not make decisions for (or instead of) people.

APPLICATIONS OF AUGMENTED INTELLIGENCE IN CONSTRUCTION

Already used in health care, manufacturing, finance and customer service, augmented intelligence has been slower to find footing in construction. Recent research reports published by Dodge Construction Network highlight three examples where augmented intelligence is providing tangible value for contractors, although none are widely adopted yet.

1. Augmented Intelligence for Construction Jobsite Productivity

Commercially available solutions (e.g., Versatile) apply augmented intelligence to contractors’ jobsite performance data to identify patterns, predict problems and suggest improvements. But, to be most effective, it requires accurate, complete and consistent data across projects.

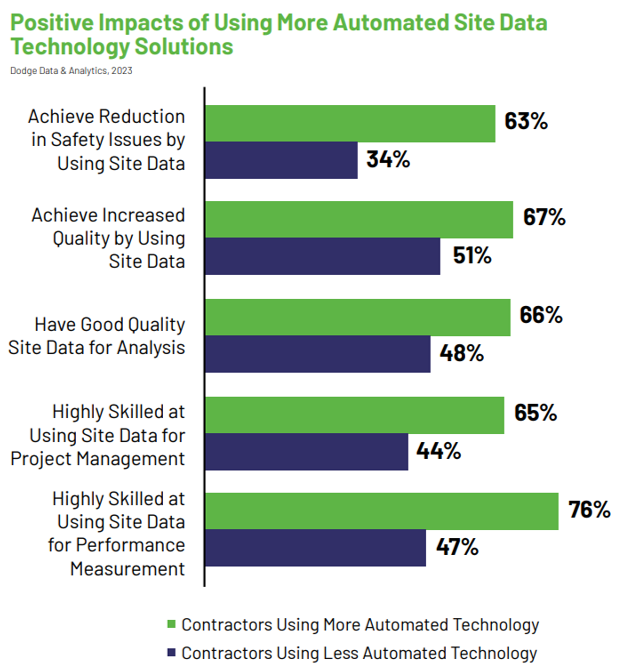

Dodge’s Measuring What Matters: Unleashing the Power of Site Data to Enhance Construction Performance report, which studies how contractors currently collect and analyze seven critical types of jobsite data, reveals that between one-third and two-thirds have frequent quality issues with data accuracy, completeness and consistency.

and analyze seven critical types of jobsite data, reveals that between one-third and two-thirds have frequent quality issues with data accuracy, completeness and consistency.

The report identifies two likely root causes of data quality issues:

- Frequent use of manual methods that can be prone to errors, omissions and inconsistencies.

- Extremely infrequent use of automated methods (including AI-enabled tools) that can dramatically improve data quality.

- Importantly, using automated methods correlates to more benefits and greater competency at effectively leveraging site data to improve processes, findings that should drive more adoption.

2. Augmented Intelligence for Construction Jobsite Safety

Dodge’s Safety Management in the Construction Industry report examines U.S. contractors’ use of 11 technologies specifically for jobsite safety.

- Currently, only 5% of contractors report using visual monitoring with AI (e.g., Newmetrix and other jobsite camera- based safety solutions), ranking it 10th out of the 11 solutions studied.

- But importantly, it ranks third for usage frequency, a strong indicator that it provides value.

- Also, another 9% express interest in adopting it in the next 12 months.

Dodge categorizes visual monitoring with AI as “poised for growth” among these 11 safety technologies because those few users are indicating high value, which usually encourages wider adoption.

3. Augmented Intelligence for Construction Fleet Safety

Most contractors have multiple vehicles working on jobsites and public roadways. AI technology (e.g., Motive) can now analyze dashcam and perimeter camera data to improve vehicle safety.

Dodge’s AI-Based Camera Systems and the Future of Construction Fleet Management report reveals that:

- Operator errors are the leading cause of construction vehicle accidents and near-misses.

- However, only 17% of contractors use any kind of technology to monitor operator behavior and identify risks around the vehicle, including just 1% using AI-based solutions.

Still, that 17% of contractors report powerful benefits.

In addition, across other vehicle- intensive industries (e.g., trucking), companies using AI-powered cameras to support operator coaching efforts report 50% fewer accidents. So again, usage in construction should increase markedly as the value becomes more widely recognized.

HOW TO ENGAGE WITH AI

AI is the Taylor Swift of construction technology these days. It is the hot buzzword on every vendor’s lips, and they can’t say enough great things about it. However, as with any innovative technology trend, each vendor is somewhere on their journey toward genuinely embedding useful AI capabilities into its offerings.

innovative technology trend, each vendor is somewhere on their journey toward genuinely embedding useful AI capabilities into its offerings.

So, how does a construction company get productively engaged with AI and not just distracted by shiny objects?

-

Use Commercially Available Construction Technology Solutions That Incorporate AI

First, identify processes that could be improved by carefully analyzing performance data that most companies simply don’t have the time and resources to do internally. These include schedule compliance, budget compliance, safety performance, construction quality, jobsite logistical efficiency and labor productivity.

Then, ask vendors about AI capabilities that address those specific issues. Consider piloting promising solutions and determine in advance how to measure their success. This approach focuses AI on a company’s identified needs rather than force-fitting a vendor’s AI value proposition of the moment onto its processes.

-

Applying AI to a Company’s Existing Internal Data

A company can experience AI’s strengths (and weaknesses) by focusing one of the general purpose AI applications (e.g., RapidMiner, Orange, IBM Watson) on data the company already has and seeing what value it provides. Suggestions include:

- Requests for proposals and proposals. After ingesting past examples, staff resumes and company history, AI can produce a first draft of a new proposal. With additional data on current workload, it can be taught to advise on the suitability of a potential project for the company’s capabilities and available capacity.

- Requests for information from past projects. This exercise can identify the conditions that tend to generate RFIs (e.g., project type, element, trade, timing). A project manager can then reduce or avoid RFIs by ensuring those aspects are clarified earlier in the project.

THE FUTURE OF AI IN CONSTRUCTION

Ultimately, AI capability will be baked into everything, and its benefits will be taken for granted. But for now, the best course of action is for each company to test, pilot and evaluate specific use cases that are meaningful to its performance and can drive measurable improvements.